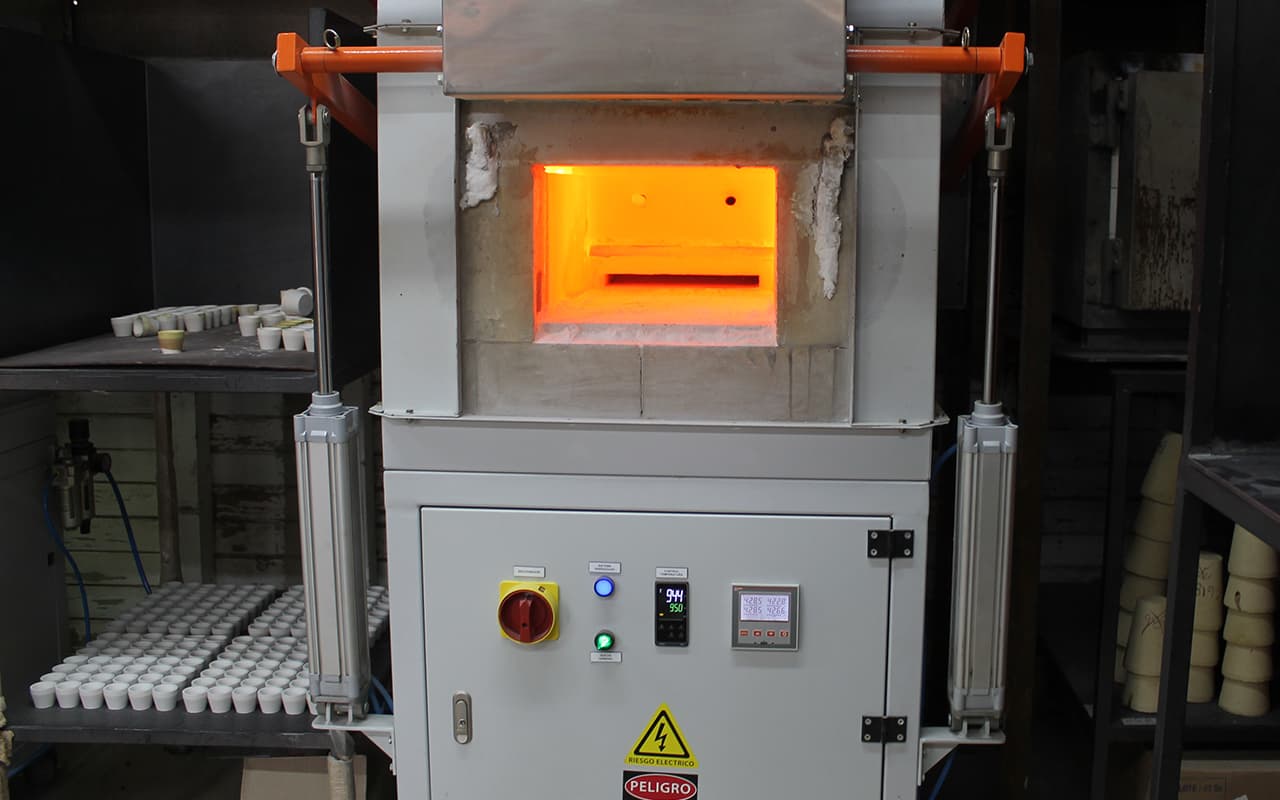

Design and manufacture of ovens and equipment for industry

Custom design and manufacture of heating equipment for industry, such as heat treatment ovens, drying ovens, ovens for dehydrating fruits and vegetables, reverberatory ovens for galvanizing.

Advantages of our ovens

- Our equipment is highly efficient and custom-designed, based on the needs of each client.

- At Enheco, we do environmentally conscious engineering responsibly, promoting the moderate use of natural gas and clean energy in thermal processes.

- Equipment designed in modules that allow easy portability in case of future modifications or relocations in production plants.

- Automation of ovens according to customer requirements and specifications.

- Selection of suitable materials and supplies for each type of process

Ovens

At ENHECO we accompany our clients in all stages of their project, providing comprehensive personalized advice throughout its execution, from the initial planning stage, through the calculation process and subsequent rigorous design of the project, to the production and installation of their heating or combustion system.

- Reverberatory furnaces for galvanizing

- Crucible furnaces for melting zamac

- Crucible furnaces for melting aluminum

- Reverberatory furnaces for aluminum melting

- Aluminum holding furnaces

- Heat treatment furnaces for aluminum (Homogenized 560°C or T6)

- Heat treatment furnaces for aluminum (standardized 220°C)

- Bell-type homogenizing ovens

- Transformer coil treatment furnaces

- Continuous brake paste curing ovens

- Rotomolding ovens

- Wagon furnaces for sintering

- Wagon kilns for enamelling

- Continuous enamelling kilns

- Batch ovens for curing flap discs and sanding rollers

Ovens and equipment for industry

We offer you our services, quality and experience, hoping to be part of your future projects.